This post contains affiliate links.

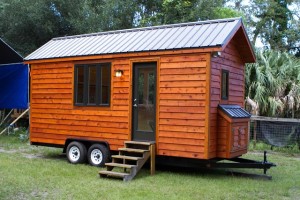

Welcome to the captivating world of building a tiny house on wheels, where creativity and craftsmanship combine to create compact yet comfortable living spaces.

In this post, we’ll delve into the detailed process of constructing the Robins Nest, the second project by the innovative Brevard Tiny House Company. From the initial design to the final touches, you’ll witness the intricate steps involved in crafting this charming tiny home.

Don’t miss other amazing resources like this – join our FREE Tiny House Newsletter for more!

Designing the Perfect Tiny Home

The journey begins with a meticulous design process. The Brevard Tiny House Company collaborates closely with its clients, creating scale models to precisely meet their needs and desires. The Robins Nest was conceptualized with a deck cleverly built over the tongue of the trailer, adding a unique and practical feature that sets it apart.

All Images © BrevardTinyHouse.com

If you ever wonder how these tiny houses are built from the trailer to the framing then you’ll enjoy getting to see it all come to life below:

One of the First Steps: Develop a Model of Client’s Design

Then Adjustments Are Made Here for the Client First

Once the design part is settled it’s time to start the build.

Step 1: Lay the Foundation on Wheels

Before the actual build commences, a custom trailer is ordered to serve as the foundation of the tiny home. To safeguard the structure and keep it roadworthy, metal flashing is added, preventing unwelcome critters from intruding and ensuring the home remains secure during transportation.

Add Flashing to Protect the House

This metal flashing prevents critters from getting in and also protects your home when it’s being towed on the road.

Step 2: Construct the Floor and Walls

The floor is carefully assembled, and insulation is added to enhance energy efficiency. The trailer is then securely bolted to the floor and wall frames, a crucial step in ensuring structural stability during the home’s journey on the road.

Add insulation to the floors. Then bolt the trailer to the floor and wall frames to secure everything (very important).

Start Framing Your Walls

When You’re Done Framing Sheath the Frame and Cut Windows Out

Then Begin Carefully Doing your Roof Framing

The roof framing is meticulously executed, ensuring the tiny home’s structural integrity. The sheathing and roof sealing come next, protecting the home from the elements and creating a reliable shelter for its occupants. The addition of house wrap helps to further insulate the tiny house.

Sheath the Roof

Seal the Roof

Add your choice of Housewrap

Step 4: Building the Interior

As the exterior nears completion, the focus shifts to the interior. Framing the interior rooms allows for a thoughtful layout, making the most of every inch of space. Loft beams are installed, providing extra space for living or storage. Staircases are carefully constructed, designed to optimize functionality while preserving space.

Add Loft Beams

Build Staircases

Step 5: Electrical, Plumbing, and Roofing

The tiny home is wired for electricity and plumbing, ensuring modern amenities can be enjoyed in this compact abode.

Install Metal Roofing

The installation of durable metal roofing guarantees longevity and protects the home from the elements.

Step 6: Transforming the Tongue into a Deck

One of the highlights of the Robins Nest is its clever use of the trailer tongue, which is transformed into a delightful deck with built-in hidden storage. This thoughtful addition enhances outdoor living while maximizing functionality.

Step 7: Windows, Doors, and Finishing Touches

As the home nears completion, windows and doors are installed, adding character and functionality. The Robins Nest design incorporates a perfect ‘twig’ beam to complement its overall aesthetics. Finally, the exterior is coated with siding, and the tiny house is expertly painted, giving it a charming and personalized appearance.

The Perfect ‘Twig’ Beam to Match the Robin’s Nest Design

Scale Model

Install your choice of Siding

Paint your Tiny House!

All Images © BrevardTinyHouse.com

Step 8: Interior Completion and Move-In

With the exterior now complete, attention turns to finishing the interior. This step involves adding all the essential furnishings and decor to create a cozy and inviting living space. Once the interior is lovingly crafted, it’s time to move in and embrace the tiny house lifestyle.

All that’s left is to finish the interior and move in, right?

Video: Three Days of Building the Robins Nest Tiny House

Sources:

- brevardtinyhouse.com/existing-tiny-houses/robins-nest/the-building-process

- brevardtinyhouse.com

Learn More About Brevard Tiny House Company

- Near Asheville, NC

- Affordable Pricing and Delivery

- Benefits of working with a team

Building a tiny house on wheels is a labor of love that requires attention to detail, craftsmanship, and thoughtful design. The Robins Nest, a remarkable creation by Brevard Tiny House Company, exemplifies the dedication and ingenuity required to bring these unique homes to life. Whether you’re considering building your own tiny home or simply fascinated by the process, this glimpse into the creation of the Robins Nest provides invaluable insights into the world of tiny house construction.

For further inspiration and a comprehensive guide on building tiny houses on trailers, we recommend exploring the tiny house construction guide dedicated to this exciting endeavor. Embrace the possibilities of living small and discover the joys of a minimalist lifestyle.

Learn More About How to Build a Tiny House on Wheels…

How to Build Tiny Houses: Step-by-Step Guide

If you’d like to learn more about the nitty-gritty details on how to build a tiny house I recommend this tiny house construction guide – it’s specifically dedicated to building on trailers.

Want More Tiny Housing Inspiration?

If you enjoyed Brevard Tiny House Company’s Robins Nest home you’ll LOVE our free daily tiny house newsletter with even more!

You can help spread the housing revolution by sharing this post with your friends on Facebook, Twitter or Email using the buttons down below. Thank you!

Related: Brevard Tiny House Company’s First Tiny Home Build

You can also join our Small House Newsletter!

Also, try our Tiny Houses For Sale Newsletter! Thank you!

More Like This: Tiny Houses | Tiny House Builder | THOW

See The Latest: Go Back Home to See Our Latest Tiny Houses

This post contains affiliate links.

Alex

Latest posts by Alex (see all)

- Her 333 sq. ft. Apartment Transformation - April 24, 2024

- Escape eBoho eZ Plus Tiny House for $39,975 - April 9, 2024

- Shannon’s Tiny Hilltop Hideaway in Cottontown, Tennessee - April 7, 2024

This looks like a great project.

Alex, I am interested in building homes like this for people to purchase. Can you tell me a little about the market?

Jeremy

Hi Jeremy- great question! The best way to build these for people is by building them on order which means… You build one exactly to someone’s requests/plans. This way you don’t have to sit on it for several months before you sell it. Most people like to build it themselves because of the labor cost savings but I’m noticing they are selling more than in the past.

Would love to see pictures of the inside of this house when finished. How big is this house? How much will this one cost?

I have plans to one day have a get away, weekend tiny house on family land and have looked at lots of plans. I felt like I found THE ONE when I saw the Robin’s Nest. It looks so doable!! Could we please see pictures of the finished inside??!

Thanks so much!

Melinda Ruth

Nice model! Oh yeah, the real house turned out nice too! But I reeeeeally like that model. And the deck over the trailer tongue. And the stairs.

Alex I can’t figure out why they’d put the metal flashing on the top side of the trailer… I’ve seen that done so many times on tiny homes on trailers… why don’t they put it on the under belly of the trailer that way you gain a good 4-6″… Any idea?

Hi Jesse I believe it’s because you want to insulate that space in between as well as build floor framing in there to lock everything together (and to create space for the floor insulation). Does that make sense?

I dunno buddy… I mean, what your saying does make sense… but it seems like you could still utilize those extra 4″ by flashing the undercarriage, put down the subfloor/insulation on top of that, and then the underlayment (if you’re even using it). And then build up from there… I mean I’m no contractor, so I still may be wrong (my knowledge is Web based and common sense… well mostly)… I just want to maximize the available space on my tiny house when I build mine.

I realise you made this a comment a long time ago but oh well…

To maximise space that does make sense but there are a few factors here; firstly, thermal bridging is a major issue with any steel framing which of course applies to a trailer. So if you put your insulation between the structure you’re going to get temperature differences being conducted by the steel which undermines your insulation. Going under and around could theoretically be done but is quite difficult with a trailer and brings up another issue in that the insulation would be vulnerable to gravel etc that might flick up off the road. Unless you clad that out underneath as well, quite complicated and you’re still using space. I think the only way to do what you’re asking without any of the downsides is to incorporate it into the trailer design somehow.

So I’m not saying it’s impossible and I have thought about similar concepts but that application is more complicated than the average DIYer is equipped for and not economic for a company.

@Zac D – It does increase the cost but it’s not complicated… Just order the trailer designed to have the floor built into the trailer chassis. Most Tiny House builders get their trailers from trailer manufacturers who will custom make them to order… Few manufacture their own trailers but over the years the trailer manufacturers have worked with the builders to optimize the trailer designs for tiny houses and being able to integrate the flooring into the trailer chassis is one of the innovations they’ve developed, along with drop axles, and other optimizations that now allow builders to achieve up to around 11′ of interior height and up to around 52″ of loft headroom… Basically gaining an extra foot over over bed trailer builds… Just watch out for the reduced ground clearance and increased weight…

You can check out Tiny Nest Project, they’ve worked with Iron Eagle Trailers and developed Sketchup files of the most common tiny house trailer designs available from Iron Eagle for Tiny House builds… Not the end all and be all of what’s available but that’s easy to find and look up…

Other manufacturers aren’t as open about what they have available but there are many custom trailer manufacturers out there…

Looks like a nightmare to tow!

Hi,

Got dilemma. I build my 16′ tiny house on a Texas Brags trailer thinking that I would build it on location and then take it off the trailer when I got it to my home site not to far away. So I didn’t attach the house to the trailer as to make it easier to get off later. Thought I cold do some exterior tie downs or something. So now I have a finished exterior shall, unfinished on the interior. Due to health problems need to sell the house. My question is, do you have any suggestions on how I could attach the house to the trailer at this stage? Another is the trailer doesn’t have any trailer brakes. Is it necessary to have these? Can I get buy without them? Any help would be appreciated.

Thank you

I would like to know what size trailer you used.

Alex… I can’t help but notice that these units are getting bigger and bigger and heavier and heavier. Many “professional builders” are popping up and the cost just keeps rising. As lenders and insurance companies get involved this kinda goes back to square one. Now the mortgage is on an expensive tiny house on a trailer and still comes with the restrictions of the traditional lifestyly of fixed stick and brick housing.

I fear that the expensive evolution of the Tiny House movement will be self defeating in the name of progress. (Money)

Sad to see this great idea heading in this direction.