This post contains affiliate links.

This is a 3D printed tiny house on a foundation built by Icon Build in 2018. According to their website, it’s actually the first permitted 3D printed home in America! Pretty cool, right? Here is a tour of the tiny home they built using 3D-printing construction technology. Check it out and let us know what you think in the comments.

What if you could download and print a house for half the cost?

Please don’t miss other incredible tiny homes – join our FREE Tiny House Newsletter!

ICON Builds the First Permitted Tiny Home using 3D-Printing Construction Technology

Images © Icon Build

Exterior of the 3D Printed Tiny House:

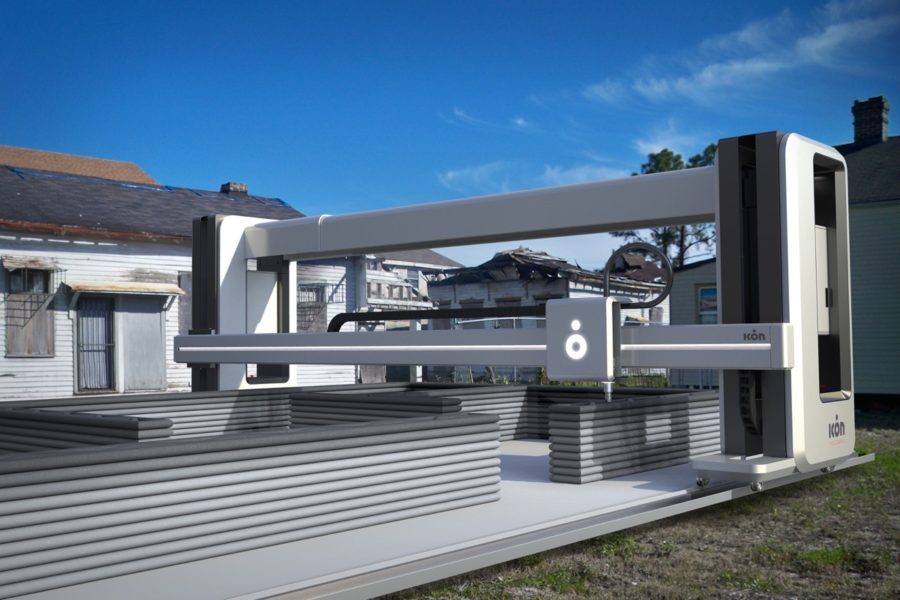

Vulcan II Printer:

Images © Icon Build

With the Vulcan II printer we’ve developed the 3D printing robotics, software, and advanced materials capable of 3D printing entire communities with up to 2,000 square foot homes. Using this technology, we can print a custom home, and we can do it quicker, with less waste, and at a lower cost than traditional homebuilding methods.

Learn more: https://www.iconbuild.com/

lease share this with your friends using the e-mail and social media re-share buttons below. Thanks!

If you enjoyed this you’ll LOVE our Free Daily Tiny House Newsletter with even more!

You can also join our Small House Newsletter!

Also, try our Tiny Houses For Sale Newsletter! Thank you!

More Like This: Tiny Houses | Small Homes | Builders

See The Latest: Go Back Home to See Our Latest Tiny Houses

This post contains affiliate links.

Alex

Latest posts by Alex (see all)

- Her 333 sq. ft. Apartment Transformation - April 24, 2024

- Escape eBoho eZ Plus Tiny House for $39,975 - April 9, 2024

- Shannon’s Tiny Hilltop Hideaway in Cottontown, Tennessee - April 7, 2024

I with another person could build this faster probably for less money. it’s not a fast process. And notice how rough the walls are will collect dirt and be very hard to keep clean. So you need to put facing over it increasing work, cost.

If you want a fast, low cost home, get SIP with 3/8″ stucco faces with wood grain in brown, etc.

I didn’t catch how long it would take to build. Does climate affect where and season of a 3D printed home? Is Central/South Central MO the right climate?

@Donald M. Toth – It was printed under 24 hours and what it prints with is either concrete or a mortar mixture. But like the roof, you don’t have to use it for the entire house and it’s simple enough for a 3D printer to do things like leave a wall cavity so you can blow in insulation or leave wall penetrations for vents, etc. and not just for doors and windows.

Though, this company is specifically using it for low cost housing and sometime this year will be deploying it in El Salvador to produce around 100 homes for a housing project there… The idea being both low cost and being able to construct homes even where normal building materials may be in short supply as a mortar mix can be made just about anywhere…

The prototype shown is 650 Sq Ft and was done for around $10,000 but the 100 homes they’re going to make will only be $3,500 to $4,000 each and the printer can handle up to 800 Sq Ft… Though, the technology can be used to produce houses up to 2000 Sq Ft…

CNC printing is still cutting edge technology for home construction. The machines have options that can install utilities and insulation as it builds the structure. It also can work horizontal and vertical and has trowling capabilities making a smooth wall much as the floor. The robotic arm can place lentils girders and steel corrugation panels for multi-story homes.

The concept is becoming a reality. The design of a footprint is imagination.

That’s not really the point. The first inkjet printers created very crude lettering and lines that would not be acceptable today. They were also pretty expensive, as was the ink. As to the texture, some people like a rough texture and pay others to create a very rough surface on stucco. My neighbor in California did that and he loved it. I expect this technology to improve with time.

That said, I was a bit disappointed in the shape, basically a bunch of straight walls. With this technology, you can create shapes limited only (almost) by your imagination. Curved walls, wiggly walls, arches, spiral staircases, etc. Many of those shapes are difficult and expensive to create using traditional lumber and forms. I look forward to seeing what this can do when someone really pushes the design envelope.

Jerry makes several good points. I’ll 2nd the point on rough walls and add how difficult it is to build out from same. Curved walls are usually a waste of space. Running utilities through the walls is a challenge but not as much as making repairs later. Spend a few years ‘printing’ mud huts in a clearing to learn and get up to speed or print barracks as the Army suggests. Apply the technology to ‘dumb’ projects before printing a hi-rise.

Even so, still damn sight quicker construction than any other building method. And to use SIP’s you haven’t factored in the time to design the right size panels, wait for them to be manufactured, then shipped to your location and then… oh dear, you need to create the foundation, did you forget? Oh… and which panel goes where and in which order etc etc etc.

Not it’s not quicker. They have built a stick built in under 24 hrs 3x this size. My stick built TH about this size only took 2 days and only that because I’m 80% handicapped with a helper and built a wood floor.

And you didn’t include design, building and transport of the printer or the fact it is only 20% of the build. You do understand both need a foundation? Or do you think they print that too?

Why did you try to make SIP look hard when as easy as it is to set up the printer?

Maybe you shouldn’t have had a helper if he handicapped you 80%. Just joking… bad phrasing on your part.

I was merely pointing out that the time frame covers all preparation, not just the build itself. A point which you acknowledge. And of course, every building needs a foundation of some sort. Whether by poles, flat earth or concrete slab foundation. I’m sure there are many other types as well that I’m not aware of.

Design by the printer is, as I understand it, a computer design that is pretty much bog standard for the printer. And yes, you do make a good point about building the walls is only 20% (give or take) of the build. But then you could say something similar of a standard build too. The external walls are only a part. One must construct a roof, doorway frames and the doors themselves, internal walls etc.

But it is incredibly strong… and as someone else mentioned excellent for areas where typhoons/hurricanes etc are a more common occurrence than in locations where these are less of a problem.

How about insulation values and the energy codes for these homes ?

Concrete tends to be a good heat sink which slowly releases that back into the home during the cooler parts of the day. Of course that possibly may not be applicable in areas where there is heavy snowfalls for a goodly part of the year. Think northern states of the US and Canada.

This house doesn’t appear to be insulated at all. I imagine square corners are possible, but this is not something to ‘download and print’ by the look of the machine that actually does the printing. Not all site are nice and level and easy to set up on like this. Low cost one level tract housing is about the only place for something like this. All the electrical appears to be surface mounted in conduit as well.

Leveling is usually part of building process, especially if you’re going to put down a slab foundation… Virtually no ground comes naturally level… So, by the time there’s a foundation for this to build on top of it would already be level…

Anyway, this is actual meant to be easily transported by truck and used in developing nations for quick and low cost housing…

It basically 3D prints mortar that can be sourced pretty much anywhere and this prototype was done in less than 24 hours and only for $10,000… They plan on deploying in El Salvador this year, the prototype was made last year, to make 100 homes and at that number the cost drops to $3,500 to $4,000 each and it can handle up to 800 Sq Ft with this prototype being 650 Sq Ft…

Would make far more sense to me to start by building an estate or village or similar of small huts/houses for the homeless or those whose present houses are falling down around them in slum areas. After the techniques are perfected then go on for more elaborate dwellings. If its so cheap and fast then move it to somewhere like California where insulation isn’t such a problem and build a few communities for the homeless or slum dwellers.

I”d like more information on how to be involved in the El Salvador project. Are they asking for volunteers for the trip? Or is this strictly a private event? I renovate houses in Atlanta presently but would like to be involved in this. Who can I contact?

[email protected]

They’re working with a charity organization, New Story… So they would be the ones to contact for volunteering…

https://newstorycharity.org/volunteer/

I don’t see any wood/steel structural supports. How stable is this building?

It’s basically a concrete structure that was 3D printed one layer at a time… So pretty strong and depending on the mixture and design can be made to handle hurricanes and up to over 8.0 Richter scale earthquake.

Though, this company is focused on making it more affordable and more easily used with locally sourced materials. So they’re not pushing the limits of the technology but it should still be stronger than an equivalent structure constructed from cinder blocks and it had to be able to meet the requirements for a permitted structure…

Is there a direct email for ICONBUILD? on the website there is only a form to fill out to get more information. Also does anybody know if this company has a whatsapp number where they can be reached. I ma located in Ecuador, and see this as an attractive way to build inexpensive housing for low income people.

Good comments, indeed. Today the 3D is a bit more sophisticated. It can level grade for slabs to a point, places the floor as it builds the underground utilities or make wall supports for beam constructed wood floor. The idea of the new genoration printers is to have multiple heads delivering different materials in the correction locations. They also assemble the utilities in the wall and floors via a thermal connection on 8-10″ length pipes for water, sewer, gas and electrical. It also places insulation in the walls. The machine also places headers over door openings and window openings. As each floor fnishes it sets the steel joist and steel deck then places the concrete floor if used, troweled. As the machine builds the walls it trowels both sides smooth, in and out. Ecept for the trim, the sills are placed for window and door frames. It truelly is a system to behold. I would like to see the spiral staircase mentioned above!

3D printed homes are mostly being used for areas that have been affected by severe storms, such as Haiti and the Bahamas. I’m a journalist and just wrote an article about these homes…the sky is the limit. You can use any material (concrete is ideal for hurricane areas), print any shape, and it’s done in 24 hours. Another 24 hours to install windows, doors, etc and you’re good. It’s a quick, safe, cheap housing option for those in need. These basic homes run about $4000-4500.

Someone brought up insulation…I don’t know if any/much is needed with a concrete home in a tropical area. Again, these homes are built to withstand extreme elements (hence the windows up high) and survive.

Hi April, thanks for these insights!

Hi April, since you’re interested in this construction method, I thought you would be interested in another more mature, durable and cost effective system. You may already be familiar with Monolithic Domes and EcoShells. They are more efficient and durable than the 3D extruder designs, and can be steel, fiberglass, or basaltic roving reinforced for strength and durability while being rapidly built at low costs, particularly in less ideal circumstances and by local labor for employment opportunities if preferred vs more mechanical solutions.

Here’s a short version of the article I wrote:

The Scoop on 3D Printed Homes

3D printing has created a buzz since the mid 2000s, but 3D printed homes may be the future of architecture thanks to low costs, high quality, unlimited customizations, and an unbelievable amount of time-saving.

How It Works

The printer starts building from the ground up, creating the walls and floors by churning out layers of concrete, which is completed in a day or less. A conventional roof, doors, windows, and utilities can be installed a day later. Most of the process is automated, including mixing the materials, and there’s almost zero waste. Houses are printed for under $10,000, safe and built up to code.

The Sky’s the Limit

If you take a look at some of the 3D printed houses, you’ll see a range of uniquely modern buildings. 3D printing has fewer architectural limitations which allow for more creativity in design. They can create any shape and combine any number of materials. You could print a round home or Dali inspired spiral staircase-shaped casa if you so desire.

A large, futuristic office building was erected in Dubai for $140,000, which is quite a bit less than the average price tag for a basic home in America. It only took 17 days to print. It also eliminated the notorious labor abuse which is prevalent in UAE.

Saving the World

For those living in areas that have been affected by or leveled due to storms, 3D home printing is nothing short of a miracle. The home’s cement mixture can be made to withstand extreme weather conditions and endure power loss. Instead of being relegated to tents and lean-to’s, people have access to real, quality housing for under $4000.

3D printing for homes is the housing of tomorrow – today.

Pretty doggone amazing!

Can this system be adapted to use “Hemp-crete”?

A few questions concerning the structure. How is the structure anchored to the foundation? How about reinforcing in the wall. Since most 3d printed structures are considered hollow, are there any reinforcing of the walls. Has anyone done any testing of the walls that shows the bond of each layer? The concept is great, but there are a lot of questions when it comes to the structural integrity of the structure.

Love it

I love the design layout and the light interior. What a gorgeous porch area outside. This one’s a winner!!!!