This post contains affiliate links.

Acquiring and preparing a trailer for your future tiny house can be stressful and costly but it’s one of the most important parts of your tiny house if you’re building mobile because it’s your foundation.

For most people, the trailer is actually the single most expensive item that you’ll buy for your tiny home. And rightly so, as it’s going to be the foundation, right?

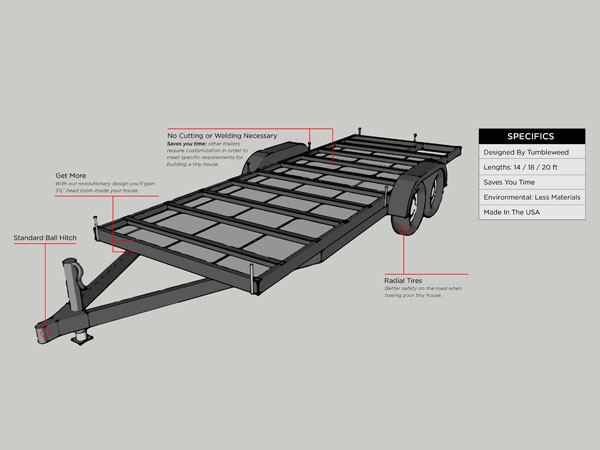

To address this problem and to make things easier for people like us who want to build tiny cabins that are mobile Tumbleweed Houses is now offering trailers specifically designed and built for stick-built tiny houses (on wheels).

Four Trailer Sizes with Several Design Options

There are four sizes you can pick from and two trailer options right now which are:

- 18′ utility trailer (~$4,200)

- 20′ utility trailer (~$4,500) deck over trailer (~$6,100)

- 24′ utility trailer (~$5,800) deck over trailer (~$6,600)

- 26′ utility trailer (~$6,100) deck over trailer (~$6,900)

You can have your trailer delivered straight to you if you’re in the United States for an additional $500-$1500 depending on where you live. Or you can pick it up for free at one of four locations in the U.S. (listed below).

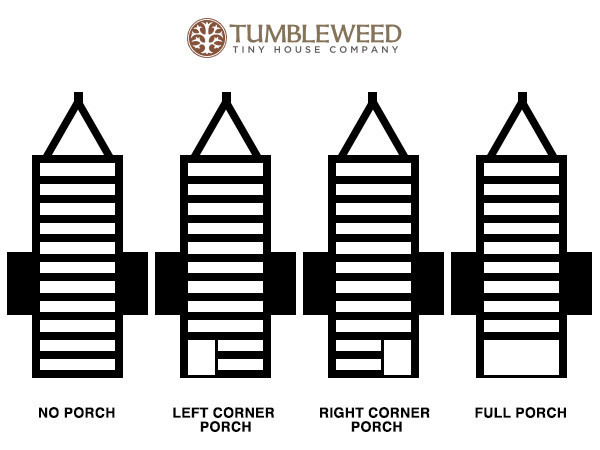

Then you can also pick four different styles within each size:

- No Porch

- Corner Porch (Left)

- Corner Porch (Right)

- Full Porch

Check it out below:

Pretty cool, right?

Utility Trailers versus Deck Over Trailers

Images © Tumbleweed

Free Pick Up Locations

Tumbleweed now offers a few pick up locations that might be near you:

- Chambersburg, PA (your custom trailer will be ready in 6-8 weeks)

- Colorado Springs, CO (your custom trailer will be ready in 6-8 weeks)

- Florida (your custom trailer will be ready in 6-8 weeks)

- Portland, OR (your custom trailer will be ready in 6-8 weeks)

Things to Look Out for when buying Used

Side note before you buy a new trailer: Yes, you can save a lot of money by acquiring a used trailer and putting lots of labor into it so it can be ready for up to 10,000 lbs of “house”.

This means your axles have to be in good shape, they must be able to handle that weight and you’ll also want to check your:

- Tires

- Springs

- Flashing

- Tongue length

Makes sense, right? You just want to make sure all the essential parts are in good shape and make the necessary repairs.

Besides that you also want to obviously look at the overall condition of the steel frame.

Since I’m not an expert builder or handyman (I’m okay at all that but I’m better with a keyboard and computer)..

So me, personally, I’d rather work, save up and buy one of these brand new ready made custom trailers and get the project rolling rather than finding used and having to work on it for several days, weeks, or even months (because that’s not what I’m good at).

So if you’re anything like me in that aspect, you might want to seriously consider Tumbleweed’s custom trailers because they’re well built, made for tiny houses, and it will help get your tiny house built faster.

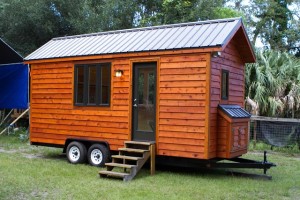

And if you’re a DIY type of person (that’s awesome!), then this is how a prepped tiny house trailer should look like after you’re done stripping it down, replacing parts, strengthening it, etc.:

Video Tips on Tiny House Trailers with Art & Meg at Tumbleweed

=> Order your own Tumbleweed tiny house trailer customized & delivered to you here.

Join our free daily tiny house newsletter here.

You can also join our Small House Newsletter!

Also, try our Tiny Houses For Sale Newsletter! Thank you!

More Like This: Tiny Houses | Tiny House Builders | How To Build Tiny Houses | THOW

See The Latest: Go Back Home to See Our Latest Tiny Houses

When you build your tiny house on wheels how do you plan on acquiring a trailer? Will you get a used one? Will you have someone make one according to your specifications/design? Or will you order one from Tumbleweed? And if you found this post helpful “Like” and share using the buttons below. Thanks!

This post contains affiliate links.

Alex

Latest posts by Alex (see all)

- Her 333 sq. ft. Apartment Transformation - April 24, 2024

- Escape eBoho eZ Plus Tiny House for $39,975 - April 9, 2024

- Shannon’s Tiny Hilltop Hideaway in Cottontown, Tennessee - April 7, 2024

Wow, a custom trailer !

They almost look like one could use the metal cross members as the floor joists.

The metal enclosed bottom is perfect. It will keep out mice, wind, bugs, and hold in insulation in the floor.

Great !

Erik,

When building a house on our trailer you can build the sub-floor directly onto those metal floor joists. This means that you’ll also gain approx 3″ of interior head-room in your house.

The metal flashing pan comes standard.

How would you attach the sub-flooring to the metal joist? Are they 16 oc? And what is the length and height of the wheels/wheel wells from the trailer bed? What length measures out from either side of the wheels wells and is it different on the different lengths? What method is used to extend the framing out and over the trailer bed and wheel wells to make an 8′ interior? How high from the ground does the trailer sit? Is a special permit needed to tow a loft height trailer? I thought if the final construction was under and certain size and weight no special permits or drivers license is needed…So would it be legal to tow an 8’6″ width x 24′ long x 13′ or 13.5′ high? I want to build a wheel chair accessible tiny house on wheels, which call for a minimum width of 30″ to get around in so an 8′ interior is crucial.

to get an actual 8′ clearance inside then add 3 1/2 ” to ea side

for stud walls, lets say 1/2″ interior wall covering and 3/4″ exterior wall covering gives you a total of 8′ 9-1/2″. this not including your exterior trim may protrude a bit further then you have your roof edge ( to keep water from not dripping directly on exterior walls), you have passed the DOT max allowed for road usage of 8′ 6″ unless you obtain a wide load placard.

I’d think if you were only going to have a one-story house, you could get by with using 2×3 instead of 2×4 for the studs – or even go with aluminum walls with strong corner supports, and get your full 8′ interior that way. More of a camper or rv style build rather than traditional stick-built house style build on the walls.

great idea! However I couldn’t find nothing about axles, brakes and suspension which are really important. I would appreciate the option of an extended towing bar to accommodate some exterior storage space.

As Frances said a fold down porch is much more space saving. When you add an RV style awning you can even sit there. Beside that it protects the rear end when on the road.

This might be a dumb question, but when he builds up the floor forward on the hitch and says that that adds 3.5′–what does that do to the house’s actual dimensions? Would that, say, mean that a 14′ trailer actually had 17.5′ of interior space? Or does it mean that the trailer is only, now, a 10.5′ trailer on the road?

I didn’t see anything about 3.5 feet of extra length? Are you sure you weren’t seeing a reference to the 3.5 inches of extra headroom, because the subfloor can be installed directly to the trailer, with insulation in between those cross beams – instead of building the floor section on top of the trailer deck?

Oh! You’re right. That’s what it was. Thanks!

A couple of things to keep in mind about these trailers:

1) If you do plan on building your subfloor into the trailer’s existing structure, be sure to use plenty of expanding foam to seal against invading insects. There’s lots of wiggle room between the welds that hold the flashing to the cross members, which will allow insects and other critters in unless you seal properly with expanding foam.

2) The actual trailer with is only 6′ 10 3/8″, so you will have to plan on how to extend your sides beyond that to take up as much of the legally allowed 8.5′

3) Depending upon the state you register it in, the ball hitch may not be sufficient for a load over 5,000lbs.

If you are going to seal the ‘floor flashing’ make darn sure you have a vapor barrier inside the insulation. It could pick up a bit of condensation, and then stay wet ( I live in wet Western Washington, and that is what structures like to do).

There are ball hitches (2 5/16″ + ) that are designed for WELL over 10,000 lbs, depending on the accompanying hitch, vehicle, and equipment. The SAE defines four classes of hitches. Class IV is good for up to 10,000lb trailer weight.

Thanks for mentioning the vapor barrier, and for the details about ball hitches!

If you use ridged, form fitting, expanded foam board insulation, you don’t need a vapor barrier.

Fibre-glass and other types of insulation that can attract moisture or settle and lose effectiveness, are not recommended.

Be mindful of open cell vs closed cell foam. Not all foam is created equal, and most aren’t meant to be exposed directly to elemental forces such as moisture, which can literally disintegrate foam structures as it loosens the bonds between cells. Because the foam boards aren’t air tight fits, it’s still ideal to use vapor barriers, in my opinion, because your actual subfloor is exposed in the same channel of environmental influences, and your subfloor is likely to be plywood of some sort, and it most certainly does not appreciate any amount of moisture.

The best sealer for the pans id automotive seam sealer. This lasts for decades and is cheap. Eastwood or most larger automotive stores carry it. It is brush on so is easy to apply. A rubber spray on undercoat is a really good idea also.

But is the expanding foam green, as in eco-friendly? I had thought I might use insulation made from hemp. Do you know what eco-friendly steps other tiny home builders have used? Thanks.

Hi Alex,

Great to hear about this development. 🙂 As a heads up, Kate over a najhaus.com has a wonderful post on her tiny house trailer she designed with the help of Portland Alternative Dwellings: http://najhaus.com/2013/03/05/the-eagle-has-landed-the-trailer-comes-home-to-roost/

Like us, Kate worked with Dee Williams and Rob from Iron Eagle trailers in Portland to make a custom built tiny house trailer. Rob and Dee have collaborated on building at least 7 tiny house trailers (that I know of) and with each build they have refined features specific to Tiny house construction. The primary feature I noticed that stands apart from the tumbleweed design above are lowering the internal ribs for maximizing the trailer depth for greater insulation and construction space above. The tumbleweed trailers provide vertical “threaded anchor rods” to attach the framing at the flange surface of the trailer where as the PAD/Iron-eagle design offers predrilled and reenforced horizontal anchor bolts below the surface of the trailer flange. Since the height of the house is limited by DOT regulations it seems that the PAD/Iron-eagle design provides extra vertical space. I would also guess that the rib design of the tumbleweed trailers would allow the metal to conduct cold, around the insulation, and directly to the subfloor. Both designs are effective, safe, and likely the best trailers for tiny houses available. I just find it interesting to compare and contrast the strengths of the designs. 🙂 Cheers!

Logan thank you so much for all this info. I’d like to do a post based on it this week or next week if you wouldn’t mind helping.

Yes, I went through the same thinking and decided to go with the PAD/Iron Eagle design. I liked that the subfloor frame was set within the trailer bed and bolted horizontally. It seems like that will keep it more secure on the road – inset versus like a cake on top of plate that could slide off. I don’t imagine this is actually a concern in the Tumbleweed design if you have enough bolts, but you do lose the extra height unless you put the subfloor right on the Tumbleweed trailer cross ribs. In addition to the 10 horizontal bolt holes (5 on each side), I will also be attaching the walls vertically via tension ties to the angle iron welded to the side rails of the PAD trailer.

I am also concerned about the thermal bridging where the metal of the trailer meets the floor (on any trailer plan). I am planning on following Derin William’s (http://www.shelterwisellc.com) example of building the subfloor frame about 1/2″ smaller than where it will drop into the lowered PAD trailer bed, putting closed cell rigid foam board in between the wood frame and the trailer sides and then bolting the whole package together via the horizontal bolts and spacers. This way there is a thermal break on the sides, front and back where the trailer frame meets the floor frame. I am also considering positioning my floor joists so they don’t line up over the metal cross ribs, so that there is a thermal break there. On the PAD/Iron Eagle trailer design, the cross ribs are made of a smaller width of steel to save weight and aren’t a necessary part of supporting the floor joists.

I’m debating whether to use galvanized metal flashing vs. treated plywood due to the vapor issue, and how to provide an thermal break between where the cross ribs meet the undercarriage. Thoughts?

The thermal bridging issue may not be an issue depending on where you live and it does seem like both designs provide excellent benefits for tiny houses. Interested in hearing from others on this!

The subfloor is great, but the width is a deal-breaker. Why in heck aren’t these built to easily accommodate the legally allowable 8ft5in width? Surely it wouldn’t cost much more.

Does anyone know where the wheel fenders are located in the 20 foot design of the TW trailers? Also the exact dimensions? I have looked everywhere on the web. I’ve been planning my TH around approximate locations and I’m ready to pin it down exactly. Example: 10.5 feet aft front edge.

Go to their website and download the trailer plans. There are drawings of each trailer .

Yeah, but no mention of how high the wheel casings are. 🙁

I think you should offer a 5th wheel type trailer. You know, one with a goose neck. Maybe say 26 or 28 feet long which might encourage shorter roof lines.

That’s a good idea. I hope they do so, too. So far, they have no plans that are designed for 5th wheel trailers though. But maybe soon? Thanks!

Hi Alax I am building a tiny home on a fifth wheel traler it’s 8’6″ wide and 33 ft long with over hanging

We bought a 20′ tiny house. It was very inexpensive to buy and we got to try out the TH living, something I strongly believe in! What we found (my husband is disabled) is that 24 feet isn’t quite enough length to accommodate his adjustable bed and a place for me to sleep in the same room. We need that extra 4′ length for the beds in the bedroom. A loft would still be nice for company. So, when we buy/build we will be looking for a bit longer that the Tumbleweed trailers 🙁 I know that many of those in the TH movement are young, but some of us are older, can’t do stairs and still love the homey feel of a real (tiny) house. I would love it if there were more of these being built in the south, especially Florida. I do very much enjoy the TH news letter!!

Thanks for sharing Darleen, wishing you the best! Alex

These seem like a great idea, but from what I can tell, the max width you can build without adding floor framing is 6′-11. I would love to see these in a full 8′-6 preframed configuration. If you want to maximize your width, I don’t see how you can get by without reframing the floor in wood which essentially eats up that 3.5″ height savings that would have been afforded by the preframing.

Anyone making these in a 16ft option? Seems like an optimum size. ..less cutting, less work, quicker build.

Thanks to those who contributed their honest feedback regarding the TinyHouse “workshops”, bad attitudes etc. A program is only as good as its worst experience. I had my doubts about paying the incongruous asking price for their “workshop” -which I noted is not a workshop at all but a lecture. Then there’s travel, lodging, and food costs. For a lecture? Ridiculous! I don’t think so. Those who offer “hands-on”, and appreciate the business, will get mine.

I’m still confused and haven’t found a reason yet, why aren’t they built to the 8.5′ limit? And since they aren’t is there an easy way or instructions to get the trailer and DIY to the limit without compromising the 3″ height saved by getting the Tumbleweed trailer? I’ve had some issues trying to find solutions for this online. Thank you for your time.

Hey! I realize it’s a little late, but they reason they don’t have it going to the full 8’5 is because the wheels/wheel wells need to stay under the 8’5 limit. So, on the left drawing up above, the wheels would sit on the outside of the trailer walls. The right drawing in the same image, shows that the walls would sit on top of the wheel wells. However, it says 7’7 because they’re including the thickness of the walls, with brings it from 8’5 to 7’7.

Alex, I really enjoy your site! Every newsletter brings an even more interesting TH to think about. These options and looks may be harder to decide than a custom house on a lot! ha It just occurred to me, after looking at this section on trailers to buy….is there such a thing as modifying or building a TH on a Class A or Class C frame of an RV?? I realize there are probably reasons that this might not be feasible, but not having to buy an expensive truck to pull the TH, would be nice. Are there co’s that are thinking about this, or ones that could modify an existing RV to have wood in or outside? The metal boxes are just not cozy like these TH’s. thanks!

Thank you for your work and dedication. We own a lake lot that only allows camper trailers. We would like to build a Tiny House but want to make it a little wider (11’6″) as we never plan to actually move it on a county or state road. Do you manufacture a wider trailer or is it. Possible to cantilever between 12-18″ per side or would the wall and roof weight be too much?

Thank you again for your efforts and for any assistance or information you care to share. Dennis

I’m confused about dimensions for a deck over trailer as shown on the tumbleweed website. Why would it be that the traditional trailer has a maximum height of 13’6″ while the deck over only allows 11’6″? It makes no sense to me.

My understanding of the difference between utility and deck over trailers is that the platform for the deck over sits a bit higher (8-12+”) than that for a utility trailer. Enough higher to basically preclude a usable sleeping loft. The maximum height (13’6″) is technically the same for both with house but without the sleeping loft there is no reason to push the height dimension to the max. Houses on deck over trailers are generally 1 story and not built as high. Somebody correct me if I am wrong on this.

What is the difference between travel trailer camper to tiny house trailer also trailer lenght i am trying to find one at least 48 foot long want to build the way i want in travel trailer camper at least 38 foot long so what is the difference why can i get a trailer. This is i want a 8.6 to 48 long so can you at least help to findone even it is not by you and find a company and the price tag please text me on this.

Mary… In googling. I’ve found that the max length for a travel trailer is 40 ft and a combination of trailer and towing vehicle is 60 ft … IF you want to do it without the special permits. Height max is 13 1/2 ft, and width is the 8 1/2 ft.

Do you folks also offer stabilizer bars for trailers (and vardos)? I have a vardo that I pull with my SUV that needs them.

Does anyone happen to know where to find the exact measurements of a Tumbleweed trailer? What I’d like to know is the distance from the front of the trailer to the wheel well, the length (and width) of the wheel wheel, and the distance from the wheel well to the back of the trailer? In particular I’m curious about the 18 and 20 ft. models.

Go to their website, it’s in the plans that can be downloaded.

Hi, I am selling my home and wanting to buy a tiny home , how could I buy one totally ready for the road , and how much are the prices, please help me figure this out thank you. Mrs mills

has any one ever built a tiny house with a pull out slide like in a camper

Kenny… Google tiny house with slides . There are some really neat ones out there.

Looks like a very nice well built trailer. The only thing that I feel that needs to be added to the video description is when they say that it is engineered so that the axles are in the right location on the trailer to distribute the weight for the right amount of tongue weight. This is also determined by the layout of the tiny home that you are building. It would be very easy to either have to much tongue weight or not enough which could be very dangerous hauling it down the road. When building a tiny house whether it be on a custom built trailer or a purchased used one, Design your tiny house accordingly to the location of the axles.

Mike Mc Intyre,

You make an important point about axle loading.

We had a friend on VanDwellers, and she kept blowing out her front-left tire on her motorhome. We met her at the scales, and weighed her rig on each side, then front and rear axles.

Something didn’t add up… so we weighed each tire individually in a convoluted ballet. Ah! The problem: apparently, the designers of her RV failed to communicate with the engineers of her RV.

We discovered the driver-side front tire carried the weight of the starting batteries PLUS the weight of the holding tanks PLUS most of the weight of the house batteries PLUS the fresh water tank.

And she was a big girl. Big. Girl. Shopped in the ‘husky’ section. Enjoyed her buffets, and her pre-meal snacks. And her pre-snack snacks.

That poor driver side tire was put-upon to carry more than double its rated capacity. Good grief! An accident waiting to happen, all because of poor communication between the RV manufacturer’s divisions.

We’re not picking on RVs, although we see this so often, it seems like intentional sabotage…

These look like fantastic trailers, and I do love Tumbleweed too. IMO, as far as trailers go, these particular trailers are a luxury rather than a necessity. Googling Utility Equipment Trailers will show you lots of similar trailers (while they’re not customized for a tiny home, they’re easy enough to work with and build on) for 75% or less of these prices. I’m building a tiny home on an 18′ Interstate trailer right now and very glad that I went for the heavier 5-ton trailer. I was able to register it with my local Oregon DMV as a light trailer (under 8,000 lbs) because I don’t anticipate exceeding that limit. In Oregon, when you go over that 8,000 lb limit you need special commercial or “farm” plates to tow your tiny home on public roads, just as FYI.

If you’re pinching pennies, look around for other trailer options. If you’re lucky enough to have a pretty elastic budget, well, then treat yourself to a Tumbleweed trailer. Cheers!

Since most of the trailer sizes are pretty standard–why doesn’t someone offer prefab tiny home kits? Ship it with the trailer. Maybe someone does…

Excellently built trailer…! Way worth it’s price.. As structurally well engineered as you can buy… I will say this though after buying one of these trailers for you build you should strip it down and use a rubberized sealer for extra protection from water and corrosion… I know this sounds a little over obsessive and maybe it is, but I would do this the same as car manufacturers do.. I know this is not going to be on the road as much as a car but this extra ounce of prevention is worth it as nothing gets more corroded as the under side of a trailer even when just sitting….!

I would like to find out more about the tiny house and how it is installed and built my about the cost. Please send into. I would like a 18 trailer and the srtucture of house and section out only. Please send me infor and cost

Hi Sheri! I recommend getting in touch with a builder directly. This builder is Tumbleweed, and you can contact them here: https://www.tumbleweedhouses.com/company/contact/