This post contains affiliate links.

This is the story of David Rule and how he’s building his dream tiny house for less than $8,000.

He started by buying a used car hauler trailer along with whatever tools he needed and he just started getting to work and learning as he went. The result? His very own self-built, affordable tiny home shell.

Don’t miss other inspiring stories like this, join our Free Tiny House Newsletter for more!

His $8,000 Self-Built Tiny House on Wheels

Images via David Rule/YouTube

He started with this 16-ft. by 7-ft. used trailer that he bought.

Images via David Rule/YouTube

It had a little bit of rust, but he said he saw potential in it.

Images via David Rule/YouTube

So he stripped all of the unnecessary parts from the trailer and started getting right to work.

Images via David Rule/YouTube

So he added a subfloor, sealed it, and filled it with insulation.

Images via David Rule/YouTube

Once the subfloor was properly built, he started framing the walls.

Images via David Rule/YouTube

Then it was time to frame the roof.

Images via David Rule/YouTube

He used plumber’s tape to further enforce the framing.

Images via David Rule/YouTube

He also used other brackets in various corners to further secure the build.

Images via David Rule/YouTube

Including these corner brackets for the framing. This is a must in a tiny house!

Images via David Rule/YouTube

He used thinner plywood to sheath the exterior.

Images via David Rule/YouTube

And thicker plywood for the roofing.

Images via David Rule/YouTube

His tiny house is almost roofed!

Images via David Rule/YouTube

Then it’s time to weatherproof it.

Images via David Rule/YouTube

There are lots of details to take care of.

Images via David Rule/YouTube

One of them being to wrap the house to completely seal it.

Images via David Rule/YouTube

Housewrap on the tiny house.

Images via David Rule/YouTube

Seal flashing is used for the windows and doors.

Images via David Rule/YouTube

That way there’s no leaking.

Images via David Rule/YouTube

Working into the night to build his tiny house.

Images via David Rule/YouTube

Flashing before the door install.

Images via David Rule/YouTube

Installing the door.

Images via David Rule/YouTube

Metal roofing.

Images via David Rule/YouTube

Images via David Rule/YouTube

Images via David Rule/YouTube

Installing his skylight.

Images via David Rule/YouTube

Grinding out some of the rust from the trailer.

Images via David Rule/YouTube

Images via David Rule/YouTube

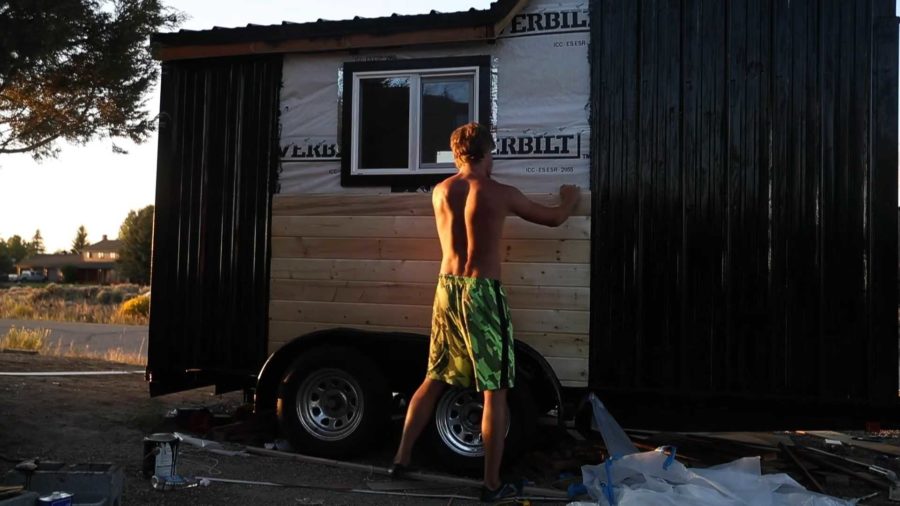

Finishing the exterior with wood and metal siding.

Images via David Rule/YouTube

Applying a stain to the wood.

Images via David Rule/YouTube

Images via David Rule/YouTube

It’s starting to look really good!

Images via David Rule/YouTube

Images via David Rule/YouTube

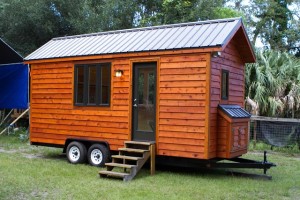

He built his very own modern tiny house shell for under $8,000!

Images via David Rule/YouTube

His friend came by to check it out and was pleasantly surprised!

Images via David Rule/YouTube

You can actually lay down and stargaze from the loft bedroom.

Images via David Rule/YouTube

Here is what his tiny house shell look like so far.

Images via David Rule/YouTube

He’s already towed it!

Images via David Rule/YouTube

Next, he’ll be working on finishing the interior.

Images via David Rule/YouTube

VIDEO: Building his Dream Tiny House for less than $8,000

Learn more

Related stories

- His Tiny House Has A REAL Bedroom And He Built It For Under $8,000

- Couple’s DIY Tiny House in Ecuador: $6,500 to Build

- DIY Tiny House Built in Her 60s

You can share this using the e-mail and social media re-share buttons below. Thanks!

If you enjoyed this you’ll LOVE our Free Daily Tiny House Newsletter with even more!

You can also join our Small House Newsletter!

Also, try our Tiny Houses For Sale Newsletter! Thank you!

More Like This: Tiny Houses | Builders | THOW | Park Model Tiny Houses | Minimaliste Tiny Homes

See The Latest: Go Back Home to See Our Latest Tiny Houses

This post contains affiliate links.

Alex

Latest posts by Alex (see all)

- Escape eBoho eZ Plus Tiny House for $39,975 - April 9, 2024

- Shannon’s Tiny Hilltop Hideaway in Cottontown, Tennessee - April 7, 2024

- Winnebago Revel Community: A Guide to Forums and Groups - March 25, 2024

Tip for DIY tiny home builders. When installing hurricane clips, framing brackets, etc. use nails, not screws. Unless you buy clips with specially manufactured screws designed to be used together. Screws are more likely to fail.

As a former licensed contractor, I respectfully disagree : )

Marsha can you explain why you disagree?

I can try. I am assuming that your concern is that the neck of the screw may not seat all the way down into the bracket hole which is sometimes the case, and that it could become a weak point under stress. However, I have in my 40 years of building had experience with both nail (the first 20 years) and screws (this last 20 years), and I find that screw necks hold up as well or better than nail necks under stress, probably because of the slight flare right under the head of the screw. I have torn apart many buildings, platforms, and other structures and the ones with nails were far easier to wrench apart if I couldn’t get my wedge under the head of the nail than were the screws that were stripped and had to be wrenched out with a wedge or crowbar. I’ve also had experiences where nail heads actually folded up on two edges under pressure and allowed the bracket to slip right off. I’ve never had that happen with screws, again probably because of the flared neck under the head of the screw. Screws are my connector of choice over nails, but to each his own, and I’m sure there are builders who have had experiences with screws that make them prefer nails. I just wanted this young builder to know that there is more than one opinion on most building materials and techniques.

A lot depends on application because screws have more tensile strength. This makes screws better for projects when joined pieces are under tension or bearing weight, like porch railings or kitchen cabinetry. Along with resistance to withdrawal pressure, which makes screws better for holding things together over time. While nails are better able to withstand “shear” pressure and will bend rather than snap like most screws would.

However, screws aren’t all equal, and there’s specifically a class of screws for structural applications that are engineered for that usage and will easily replace nails for code compliance in any and all structural applications. Some are even made to replace clips and brackets. Like Simpson’s Strong-Tie SDWC truss screws, for example, which also saves a lot of time and effort compared to using clips and brackets.

There’s also screw products that are made to be fired from a nail gun when speed is a factor that can be used in most framing applications… But screws do cost more and that adds up for large projects.

Just in a tiny house, though, it can make a lot of sense to use screws. Especially for maintenance, ability to make changes later, and as most will be movable better to resist the vibrations, etc. to better hold the structure together and not develop gaps, etc.

What a great little house! Very cute, good windows, great skylight! Wonderful!!

Impressive build! Absolutely beautiful so far. Can’t wait to see it finished.