This post contains affiliate links.

In last week’s article on passive solar design for tiny houses I briefly mentioned advanced framing and SIPs—two alternatives to conventional 2×4 stud framing.

Well, it turns out there are a lot of alternative framing systems out there. Why would you use one of them to build your tiny house?

In a lot of ways, conventional 2×4 stud framing is pretty awesome. This technology makes it possible to build houses quickly and cheaply. It’s flexible and can be used to create a wide variety of structures, including tiny houses. And it’s based on a standardized set of dimensions with which most other building products are compatible.

But conventional framing has some weaknesses, and the main one is that it’s not terribly easy to seal and insulate well, so it’s not very energy-efficient. That’s one of the five big factors we’d look for in an ideal framing system for a tiny house:

5 Factors for Framing Tiny Houses

- Insulation. Does it provide good thermal insulation and few air leaks?

- Strength. Can it stands up to the rigors of transportation, high winds, etc.?

- Weight. Is it relatively lightweight? (Sorry, concrete, you’re out!)

- Cost. Is the additional cost (if any) justified by the benefits?

- Ease of construction. Can it be built quickly, and is professional installation required?

Without further ado, on to the contestants!

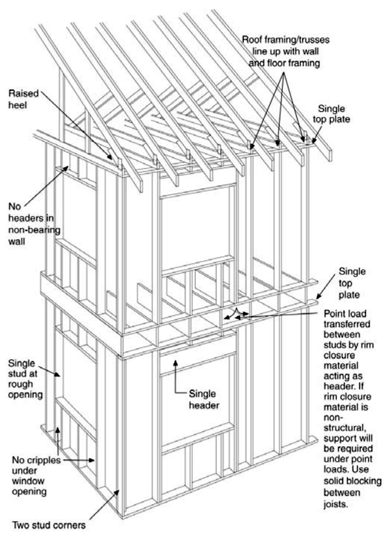

Advanced framing

The first approach is straightforward: just take conventional 2×4 stud framing and make it better. For anyone familiar with conventional framing, advanced framing is easy to learn, and it has some significant advantages—mainly, more room for insulation.

Photo credit: Building Science Corporation.

The basic elements of advanced framing are:

- 2×6 studs at 24” centers

- Single top plates

- Two-stud corners

- No jack studs

- Single headers or no headers

If you understood all of that, ten points to you! For a lot more information, Joseph Lstiburek from the Building Science Corporation wrote this great article explaining advanced framing.

The analysis:

- Insulation: Advanced framing improves the thermal resistance approximately 75%.

- Strength: Just as strong or stronger than conventional framing.

- Weight: Uses 5 to 10 percent less lumber, although the extra insulation might add a little weight.

- Cost: The same as conventional framing, or cheaper.

- Ease of construction: The same as conventional framing, once you learn the new system.

Any pitfalls? For a tiny house, there’s just one, although it may be significant. Because each wall is 2” thicker, you lose 4” of interior space compared to conventional framing.

While we’re talking about alternatives to 2×4 studs, here are a few more:

- Steel studs. A possible alternative to wood, but the metal studs sold in your local Lowe’s or Home Depot are not meant for load-bearing walls—you’d need something stronger. (See this previous article on TinyHouseTalk.)

- Aluminum framing. Common in RV construction, but isn’t the whole point of tiny houses that they’re built like normal houses and not like RVs?

- Engineered wood products. Engineered studs, beams, headers, and other components are more expensive than regular lumber, but for specialty applications they can provide higher strength.

- Engineered trusses. Very common today, and a good alternative to rafter construction for the roof. Main advantages: strong, easy to install.

SIPs

Unlike advanced framing, the structural insulated panel (SIP) is a pretty radical innovation compared to conventional framing. SIPs consist of a layer of insulating foam sandwiched between two structural skins. The foam provides a fairly continuous layer of insulation, while the skin—usually oriented strand board (OSB) or plywood—provides the structural strength.

Photo credit: Boneyard Studios.

The basic things to know about SIPs:

- Common panel thicknesses are 4-1/2” and 6-1/2”

- Panels are commonly 4′ wide by 8-16′ high.

- The insulation is often EPS (expanded polystyrene, also known as Styrofoam) but can also be XPS (extruded polystyrene) or PU (polyurethane)

- Electrical chases should be pre-installed as panels should not be cut once manufactured.

- For more, see this helpful article from the Building Science Corporation.

Related: How to Build a Tiny House using SIPs

The analysis:

- Insulation. Much better than conventional framing, and usually better than advanced framing (4-56% better, based on my rough calculation, but it will vary depending on the manufacturer anyway).

- Strength. Stronger than conventional framing, and the SIP manufacturer can engineer the panels to meet your requirements.

- Weight. There’s not a lot of data out there, but the difference is relatively small.

- Cost. Somewhat more expensive to buy, but possibly made up for by…

- Ease of construction. A good SIP manufacturer can take your plans and manufacture panels that are easy to assemble.

I’ve found two tiny houses built with SIPs and they seem to work very well. The houses are the Minim House by Minim Tiny Homes/Boneyard Studios (link 1, link 2), and the Tiny SIP House by Art Cormier, based on the Tumbleweed Walden design.

Video: Art’ss SIP Tiny House on Wheels

Wood SIPs are the most common, but other types of SIPs are available, including:

- Metal SIPs – Expensive, but strong and durable. It would be cool to see someone make a tiny house out of these.

- Fiber cement SIPs – Fiber cement is a great cladding material in some climates, but it’s also super heavy, which limits its tiny house usefulness.

- Fiber-reinforced plastic SIPs – Fiberglass and similar composite materials are used in coastal climates and boat building because of their strength, water resistance, and light weight.

Factory-built framed panels

A third alternate framing system is worth mentioning briefly. Factory-built framed panels can provide higher precision than site-built walls and sometimes higher strength and insulation as well but at a cost. If you have unusual needs or want to build a lot of tiny houses, factory-built panels might be the way to go. Some manufacturers to look into include Dynabilt, Kokoon, and ThermaSteel.

See How These Tiny Homes Were Built:

- SHEDsistence Construction Time Lapse Video

- How to Build Your Own Tiny Cabin

- SHEDsistence: The Construction

- How to Build a Tiny House: The Robins Nest by Brevard Tiny House Co.

- Art’s SIP Tiny House

That’s it for alternative framing systems. Have you considered alternative framing systems for your tiny house? Did I miss any systems? Share them in the comments below.

Whether or not you go alternative, good insulation is key, and next week’s article will be all about insulation. What fun!

This post contains affiliate links.

Vincent Baudoin

Latest posts by Vincent Baudoin (see all)

- Small and Affordable: The 20K House Project - April 1, 2013

- Solar-Powered Tiny House Prototype: the LumenHaus - March 16, 2013

- Types of Tiny House Communities: Urban, Suburban, and Rural - March 7, 2013

Either conventional stud framing or avanced framing will work but in a small house with a loft addition special consideration must be made to support the loft.

SIPS can be made by the individual and are a little more expensive and harder to run witring and plumbing through.

For a house on wheels a 24″ space between studs is sufficient but for a traditional permanent house a 16″ center stud wall will give more support to a roof and loft.

It also depends on roof bearing loads and in areas with high snow loads a proper pitch and heavier supports are required.

I am not structural engineer, but I am working towards becoming a licensed architect, and I believe that if you go to spacing wall studs out farther than the typical 16″, leaving out jack studs or king studs, or even going with a single header or no header really compromises the integrity of the structure. The absolute only way that I would think that someone could get away with spacing wall studs farther apart or removing headers is if there was a steel frame embedded in the structure itself. It would almost prove to be more cost effective to go with a 2″ – 3″ square tube frame. Another thing to consider when going with a SIP panel or something of the like is that these houses usually run 8′ wide to be able to be built on a trailer. If you decide to use a SIP panel you are going to be reducing your livable space within. It is also more challenging to run your plumbing and electrical systems in the exterior wall when it comes ready-made. I think that we have to look to more historic framing systems and maybe going with a plywood sheathing on a narrower stud, maybe even down to 1-1/2″ piece of furring. If you were to go with (2) layers of half inch plywood sheathing on each side, with an 1-1/2″ stud your wall thickness is 3-1/2″ and if you do it correctly that plywood might not need to be finished on the interior. Another idea would be to take and sandwich together plywood boards. While they would still be 1-1/2″ thick if you used (2) 3/4″ boards you could ideally make that wall as thick or as small as you wanted. Then, if you went with a narrower wall structure you could spray foam between the studs to make it more air tight. Bottom line, I believe that even thought these houses are small does not mean that the structural integrity should be compromised. That is seemingly bad advice for people that tend to build these on their own.

24″ spacing with 2×6 studs is an acceptable practice in many county building codes. Advanced framing is not a new practice. In fact it is actually an old standard being reconsidered by the modern builder in an attempt to be more green.

Erik, thanks for your input.

Advanced framing involves certain specific details for headers, corners, and other areas. You cannot simply increase your stud spacing, downsize your headers, or anything else without learning how the system works. However, properly built, advanced framing is fully supported in most building codes, although a few code officials might still be unfamiliar with it.

Moving on to SIPs, the panels come in various widths. A 4-1/2″ panel is only 1/2″ thicker than a conventional wall, and is stronger and better insulated. True, you must plan ahead for electrical wiring. As far as plumbing, it would be best to avoid running plumbing through exterior walls in the first place, but it can be done.

There are plenty of schemes for reducing the width of the wall or the amount of structure in it. The commenter above suggested 2×4 studs on 24″ centers, and you suggested several approaches. However, for anybody who wants to build up to code, these are not satisfactory solutions. Anyone trying them should be aware of the risks. For example, a 1-1/2″ plywood wall will be heavy and yet have almost no insulating properties.

Great article

Thanks, great article. When you say “metal SIP”, do you mean that the two outer sheaths are metal, or are you referring to K-tect walls, which are metal studs with stiff foam in between (and which still need some sheathing)?

Also, please post a link about the plastic fiberglass SIPs that you say are used in boats.

Hi Eric,

Sorry it took me a few days to get back to you. When I say “Metal SIP” I’m referring to a SIP with stainless or galvanized steel sheathing. They’re more common in commercial buildings but show up sometimes in houses in hurricane-prone areas.

As far as the fiber composite panels, it turns out the company I had in mind (InnoVida) went out of business in 2011, but their product was bought by another company and is now called the “Inovatec System”:

http://www.inovatecsystem.com/

It looks like another company that manufactures similar panels, Insulated Component Structures, was purchased by SIP Supply and it’s not clear whether they’re currently being manufactured:

http://commercialsips.com/component/content/article/125.html

It looks like this technology became a victim of the housing crash. My information was out of date — I should have checked. However, there may be a few manufacturers out there who still make something like this.

Found another manufacturer of steel SIPs (they have been used for some cool projects, as you’ll see on their web site):

http://www.oceansafesteelsip.com/

The Maximus Extreme Living Solutions‘ houses featured in your article “Tiny Houses to House Workers in your Dec 3, 2012 article “Tiny Houses to House Workers in Oil Fields?” use Raycore SIPS advertised as “super lightweight.” The insulation is NOT sandwiched between outer skins of board, but instead has studs embedded in polyurethane foam, and a foil skin .

That sounds like a great option. What might the disadvantages be?

Stephen,

That’s an interesting product. They call them SIPs, but I would consider them “Factory-built Framed Panels” because, as you point out, they don’t have a stressed skin. You still have to sheathe them when you install them, just like a normal wall. So you’re really just paying for a very tight stud wall, which you could also achieve using spray foam insulation or very-well-installed rigid foam. I’m not sure the foil insulation will be all that effective, either — usually you would need an air space in front of the foil for it to be effective, so if you sheathed or drywalled right over it, it wouldn’t work. In addition, whereas most SIP manufacturers will custom-manufacture your panels with all window and door openings pre-framed, this is something you do yourself with the Raycore panels.

Good article mostly but a few details.

Not all trailers, RV’s are badly made many especially the FG ones are very good and insulated. Others like Alum Airstreams are very good and just need insulation put in along with your new interior.

Don’t count out concrete as some new tech is coming out or already here I’m going to make tiny homes from. The only question is how portable they’ll be but I don’t think they need be any more heavy that stick built. Think Driv-It, STOW style insulating systems which themselves one could make a good extremely well insulated tiny home from.

I wouldn’t use OSB in SIP’s as even CDX plywood is better by far.

Another type of construction is stressed skin where the skin carries most/all the load and is very light, strong but gets it’s strength with curves with a single skin. I build boats this way and hard to beat.

I’m building a 34’trimaran in epoxy/ply and while doing the hulls, cabin it dawned on me just how well the same technics would work making tiny homes, especially very mobile ones as light and can be extremely aero, so much towing a light one may not even reduce the tow vehicle MPG from aero drag savings.

One should look into boat building technics as much to learn there.

Heck I even build my transport, lightweight EV’s from epoxy/ply for the body/chassis and works great there too.

Jerry,

Super interested in hearing more about this boat, and Electric vehicles!

With regards to SIPs, is anyone seen any data on off gasing/toxicity of the foams mentioned above? From an insulation standpoint SIPs seem like a great way to go but not if the nice tight enclosure you create ends up filled with toxic fumes. I would be very interested in hearing from someone who has come across any truly independent and specific test result from a qualified lab on the types of enclosures being proposed here. Thanks, DonC

Don,

I’ll second that — I would love to see some independent testing. Many manufacturers claim that their foams are completely non-toxic. There is are some interesting points made here:

http://www.rcgroups.com/forums/showthread.php?t=1589660

Another possible source of toxicity is the resin that is used to manufacture OSB and plywood panels. Depending on the product, this resin may contain formaldehyde, which is classified as a probable carcinogen. Columbia Forest Products has a soy-based, formaldehyde-free product called “PureBond” that is worth looking into. For a discussion of formaldehyde in these products, look here:

http://greenhomeguide.com/askapro/question/im-concerned-about-toxic-offgassing-from-osb-subflooring-and-roofing-are-safer-products-available

Finally, you’re right to point out that a tight enclosure is an air quality issue in itself — especially in a tiny house. This is an issue with ANY well-sealed system, not just SIPs. For that reason, I highly recommend a continuous ventilation system in any well-built tiny house.

http://energy.gov/energysaver/articles/whole-house-ventilation

I’m right there with you on the concern about the off gassing, and not just from the insulation, but from glues, and in particular, the glues used to bond laminate flooring. I’d much rather go with real wood, reclaimed, of course. I’ve had enough health problems – don’t want to add to them. Trying to eat really clean, and definitely want to do the tiny house thing within the next few years.

I have a question about chemicals in building materials (specifically about the SIPs walls). I have a very serious autoimmune disease that can be caused/exacerbated by toxic environmental exposures (known: silica dust, various organic/hydrocarbon molecules like vinyl chloride; possible: formaldehyde, brominated flame-retardants) – therefore I wish to build a home with few or no toxic chemicals.

What can you tell me about SIPs and other insulation options re. chemical constituents?

P.S. I majored in biochemistry at UC Berkeley, even though I live in the land of the fruits-and-nuts, I am not a garden-variety nut-case. I don’t know that my illness was caused by environmental/occupational exposures, although I do know that I have had a number of them since early childhood, but why not reduce risk…

[I hope to pursue graduate studies in epigenetics – the environmental influences on gene expression – where genetics meets the real world.]

Hi Stephanie,

Did you get a chance to look through the comment above? It addresses some of your questions. I don’t have any information about toxins relating to your specific condition, but you may be able to find some information here:

http://www.epa.gov/iaq/homes/index.html

You did not mention a lot of old framing methods used in Asia and the Orient for lightweight structures. Firstly, I have to mention the traditional yurt-style home which uses a flexible wood or bamboo lattice for wall-framing, typically divided by screens or curtains.

Second, I have to mention bamboo-framing, in general, which exists in many forms. Many of us have seen lashed bamboo in movies about Pacific Islands, but jointed bamboo is used greatly in southeast Asia. One can grow all the bamboo needed to build a tiny house in about ten years. Many insulation methods can be adapted to bamboo structures.

Third, I want to mention wire-framing. This is not a well-accepted method of building, as that it uses wire stretched over wood or steel beams to support wall structures, and is rarely utilized nowadays, though it did see some notoriety for home-built campers from the late 1950s through the early 1970s.

I am sure other framing methods exist, if we do our homework, but I just wanted to mention these three, since I have familiarity with them.

Good article! The link to the advanced framing article doesn’t work, but I found it here:

http://www.buildingscience.com/documents/insights/bsi-030-advanced-framing

HI there, your first link for the article on advanced framing doesn’t work. Are you able to update it?

Thanks!

OK… if we include traditional framing (1), I only count three more ways to build

(2) Advanced Framing

(3) SIP’s

(4) Factory framed panels

Where are the other two???

Is there any danger of the SIPs off-gassing?

Neither EPS or NEOPOR foam off-gas … the beads are expanded into blocks using an ozone friendly pentane leaving only air in the cell structure. Due to the fact these cores are completely inert they will not be subject to thermal frift or loss of R value over time. Additionally, the OSB used in SIP production contains no urea-formaldehyd.

At Ragsdale Homes, we are developing a hybrid construction technique of our own, using track tested steel cage and roll bar technology from the race car industry, adding additional strength when traveling down the road, especially when weather conditions are severe. We combine this technology with our space age SIP panel technology now being tested, utilizing NanoPure thermal tested insulation in the form of a vacumn insulated panel or VIP integrated and sandwiched in between EPS, XPS, and PU high density foam. Then, an outer skin of aluminum coated metal or steel that has a special coating encapsulates everything. The result is a panel which up to 35 % stronger than wood or metal studs, and, up to 60% lighter. The insulation factor can reach up “R” 60. A special SIP panel for the roof can have a surface similar to textured sheetrock, facing towards the inside, and, a traditional metal roof panel attached to the outside without the need for ceiling rafters. Then, there are some amazing panels available for the floor which elimanates a barrier surface, floor joists, plywood, insulation, etc. Ninety percent of the floor consists of just two panels that just snap together in the middle. The outer perimeter is secured with stainless bolts and nuts. On the outside of the SIP panels, a special coating, developed at NASA called Insuladd can be added in just about any color to further stop heat gain. Ciao Jay

Thanks Jay! Sounds really interesting

I know this article is a little old but thought I would try and ask Vincent what he thinks about a conventional/advanced approach with extra foam insulation on the exterior, like Super Insulation? I haven’t seen alot on it, but I would try to use Styrofoam and some kind of glue to completely seal/bond say another 2″ to the exterior wall and roof. A possible approach to finishing this off would be EIFS.

How would this approach stack up compared to the other methods?

Incidentally, I looked up the “Factory-built Framed Panels” spoke about above. I was disappointed to see the the insulation did not extend over the stud face, at least on the exterior side. Their product could be vastly improved in that way.

My wife and I are in final phases of building a 240 sf cabin in East Texas. We used Steel to frame it. I loved working with it. It took a bit to get used to but after we figured out which tools to use and how, it went together very nicely. This was the 1st structure we had ever build and it is incredibly sturdy. We used 12 gauge & 14 gauge structural studs, 2×4 & 2×6. We found several guides to using structural steel for residential framing. They were the key to this project going off smoothly.

Lots of reasons we used steel.

1. Stronger and lighter than wood (we’re both 50+ and did all work ourselves.)

2. No insect damage (we’re in the middle of 12 wooded acres)

3. No wood rot (we get about 46 inches of rain per year)

4. Very long lasting

5. Weatherable – we worked on project as we could afford materials. Didn’t want to worry about how long it took to dry in. Steel can sit in the rain for years compared to stick built house that needs to be sheltered within months.

The article is right, the metal studs you see at HD & Lowe’s are not made for structural building. We found that the most common supply of all of the materials and supplies were at drywall suppliers. They were very helpful in getting us materials and some advice on where to begin. Please email me if you have any questions or interest in doing a project in steel. I’m not an expert but I learned a lot over the last year. I would be glad to share.

Jay

[email protected]

Here is a link to some pictures of the progression along with a PDF of the Structural Steel Installation Guide.

https://www.dropbox.com/sh/wws6rc2v46tjb2r/AABw9zl8xFKSRsNveYnCNI6va

Thanks for sharing Jay! That would make a pretty great guest post 🙂

Thank all of you for sharing, yes I’m listening, learning and lookin up ALL the links hehehe God bless you all! Happy Trails!

http://artisantinyhouse.com/

Just in case anyone is interested in a Tiny House shell on a trailer.

Pat can make about any SIP design needed.

Cool! Thanks Mike!

Hi Alex and all other Tiny House Fans…

I’m wondering if anyone has attempted to use EZ-SIPS for a Tiny House ?

http://structuralinsulatedpanels.com/

This is an alternative SIP where you use stick framing (16 or 24 oc) 2×4 or 2×6 which also provides an external layer as a Thermal Break all in one shot and fills your walls with foam. These also come with pre-cut strips that you can peel out for wiring chases etc.

I’m intending to use these for my own Tiny (20×8) with the 2×4 walls & 2×6 cathedral Gambrel roof, all sheathed with OSB & tin roof.

Currently building a 8 X 20 tiny house out of SIPS. We also built 3 panelized homes for employees at Tumbleweed.

Introduction to SIPs of America manufacturer of very strong and very energy efficient structural insulated panels. This panel is 8′ X 24′ and is 6.5″ thick. Please visit http://www.sips.org for additoinal information.

Building green in now more affordable.

https://www.youtube.com/watch?v=Aqkc5bG8j68&feature=youtu.be

Disaster Relief project working with University of Virginia and others.

https://www.youtube.com/watch?v=PM5pSa0Xp8k&feature=digest_mon

Thank you,

Using advanced framing doesn’t lose you 4″ of interior space unless you were switching from 2×4 studs. Living in a northern climate, I’d never use less than a 2×6 wall, so the real advantages here for a tiny house are that using advanced framing techniques, one can save weight, time, and expense, and decrease thermal bridging with virtually no significant loss in strength. If you combine advanced framing techniques with careful design, such that windows and doors are sized and placed so as not to break up stud bays, you can potentially save even more.

My designs assume an 8′ 0″ width from the outside to the outside of the exterior sheathing. This leaves me with 83″ of interior width, assuming 1/2″ exterior sheathing and 1/2″ interior wall finish, and of course leaves me with 3″ of clearance on either side for overhangs siding, and exterior trim. 83″ interior width is enough to place a Queen size mattress transversely, and still have enough room to stick your hand in and make the bed. So far as I am concerned, the ability to fit an 80″ long mattress transversely is a design consideration to which all other concerns must give way.

In so many tiny house builds, I see people putting so much wood in their walls, usually because they are blinding following conventional building techniques that demand jack studs and king studs, and double headers and cripples, that the walls are practically solid wood. This severely compromises their insulation envelope, and with the spans we are considering in tiny house construction, is not only overbuilding, but adding weight that itself will result in higher dynamic loads in transport, not to mention higher fuel usage.

SIPs are great; I love SIPs. But, you can’t go down to your local lumber yard and pick up a SIP, the way you can pick up a few 2x6s and frame a wall all on your own, as time and money permit. They need to be manufactured to your design, and can’t be acquired incrementally. If you have the ability to order them all at once, you should seriously consider them.

Has anyone seen a Tiny Home on a trailer built single wall construction. I live in Hawaii and a lot of the old plantation homes were built single wall. The homes were post and pier with the floor deck built similar to a regular home. The exterior walls were built out of tongue and groove 2×8’s mounted to the base with a horizontal boards nailed top and middle. It’s a very simple way to frame. my thought was to weld angle iron to the outside of the trailer frame to carry the bottom of the boards. It wouldn’t be so good in cold climates but were it’s warm it could save a lot of time. Hiding plumbing and wiring requires a bit of planning. Its an idea I have been tossing around for a while.

This link has some diagrams and other info…

http://mjobrien.com/Papers/Loa-Bearing-Single-Wall-Construction-from-Shanties-to-SIPS.pdf

Excellent information. Was gonna use metal studs, but I’ve changed my mind. Advanced framing looks very appealing.

So I was looking into doing the advanced framing for the 2 Tiny Houses on Wheels I’m building, because I live in Alaska the houses would really need the buffed up insulation, but I clicked on the ThermaSteel link and I gotta say, that is so appealing. The walls are factory built but are eco-freindly from what I’ve read which is so important to my project. We are trying to build 2 eco and family friendly Tiny Houses on Wheels to tour Alaska in so as to share all these idea’s and knowledge about The Tiny House Movement with my fellow Alaskans. I really feel like Tiny Houses could help a lot of people here, and these Therma Steel walls, if they hold up to our winters, could be another wonderful tool for me and my peeps in our Tiny House adventure:)

Recently saw an episode of “Tiny House Hunters” for a couple in Carmel? that were putting a tiny house on their parents property and went to Portland, OR to buy their house (they bought a gray house with drywall interior and had to have it moved via a diesel rig). The house had a huge kitchen. I have been unable to locate this house on any website. Does anyone know who makes that house?

I saw a lot of general comments as well as links but I am having difficulties with insulation and ventilation questions. Most of you seem to have built in cooler or cold climates. Can the southeasterners amongst ya ‘ll ( yes, ya’ll, I’m a born and current Texan), comment? Specifically want someone in south or southeast who has actually researched and implemented a tiny house design for proper interior humidity and ventilation. I am VERY concerned with limiting indoor pollution, both from the standpoint of a person highly allergic to oaks and grass pollen (so I want to minimize air coming in) and from one who is scared, yes frightened, about both the possibility of black mold forming in insulation from interior humidity as well as the problem of using engineered materials that have significant levels of VOC s. I saw the links and other articles related both to whole-house ventilation as well as to SIP s formed without formaldehyde. But I want to see some comments from those that have actually installed whole-house ventilation in a hot, humid exterior environment such as central Texas, in a tiny or small house design. Anyone?

To the moderators, please respect email privacy. Thank you.

To the person who asked about the large kitchen, most large kitchens seem to be in “park model” designs (usually around 400 sq ft, 12 feet in width), not true tiny houses on wheels that are RV designed for open road (usually 100- 200 sq ft, 8.5 ft wide, usually 18-26 ft long). You might check out youtube video that’s about 20 min long for a guy that built a nice one with a REALLY beautiful kitchen that is the entire width and, I think, built on the axle side of the home.. Should be easy to search youtube for the 20 min video. I think his website might be something like tinyhousebuild.com. he does offer his designs, for sale, I think. Another is wheelhaus.com, beautiful, and expensive park homes. Great for ideas but I don’t think they offer their designs.

Hey I just read an article about framing a tiny house. I’m in the process of building a tiny house with my better half. We are using 2×6 studs at 24″ oc. My question is about the framing. We are torn between using framing nails (not sure which one you would recommend) or 3″ deck screws as far as it goes to putting the walls together.

Thanks,

Rob

When we say tiny house, do we really mean house or a van with some basic stuff. I enjoy the fact that living in vans looks much more adventurous, but the comfort of home cannot be matched.

Is it structurally possible to build a tiny house with furring strips instead of sheathing it then putting metal siding of all exterior and interior walls including roof and ceiling? Of course Weight was an issue thats why im asking.

I want to have a little storage room made. It makes sense that I would want to have a nice frame for it! It might be a good idea to have it made of metal, though. It would be much more durable for my purposes!

Thank you for mentioning Kokoon for structural steel construction.

Kokoon manufactures NOAH certified Tiny House On Wheels. Our KOMPAK line of structural steel framed -18 gauge- exceeds requirements of National Building Code. Our KOMPAK has Soy based foam insulation sprayed in place, firesafe, no formaldehyde. Exclusive designed trailers are NATM manufactured and ALL have 4 wheel brakes. 7 x 18 compete shell start at $8995 (includes NOAH certification) Use your floor plan and finish as you like!!

PASSIVE SOLAR DESIGN: The More Sides the Better

The last low-cost house i built involved a hexagon(6 sided) . This was an excellent shape, as is an octagon (8 sided).

This SOUTHERN HEMISPHERE house was in the sub-tropics, but winter could be chilly, and the walls did not have any insulation.

Change the word ‘north’ with ‘south’ if you are in the northern hemisphere.

The southern facing walls had NO windows. This is where the summer sun comes into the house.

The northern-facing walls had maximum windows and no veranda cover (unless it was fiberglass). This is where ONLY the winter sun comes in to the house.

You do need to calculate the exact angle of the winter sun and its’ relation to windows and overhang on the northern side, to blockout summer sun and & increase winter sun.

The materials for this house would be approx $30,000 AUD, these days, but only the windows were recycled and the bathroom was not complete.

It had 3 levels, like a Pagoda, or bird-house.

Even cheaper, is to build a square or rectangular gable roof with load-bearing frame, and create a hexagon or octagon underneath.

Hi,

Just thought i let you know i have built my 320 sgft tiny house on a 5th wheel tr frame using metal sips. walls and roof. used metal studs for floor. not standard use or construction using the sips, just my idea of how to put them together without knowing what we were doing. worked out great. been living it it since 2013

Plz check Singcore panels. Are they suitable and affordable for THOWs?

I plan to use marine ply (or similar ) with lightweight framing for the walls, and to support the curved (i.e gypsy wagon), corrugated iron roof, as formwork supports an arch. Pity I can’t add a pic!